News from our world of plastics injection moulding and TFC

Pekago is now also ISO 14001 certified!

14 Apr 2025 We are proud to announce that Pekago has officially been certified according to the ISO 14001 standard. full story

14 Apr 2025 We are proud to announce that Pekago has officially been certified according to the ISO 14001 standard. full storyClosure during summer and upcoming national holidays

31 Mar 2025 During the summer Pekago will be closed for a short period.

31 Mar 2025 During the summer Pekago will be closed for a short period.The same goes for some upcoming national holidays.

In this message you can find when we are not available. full story

TSG in the Spotlight in Sweden

11 Nov 2024 TFC (thermo foam casting) or SFM (structural foam moulding) is still relatively unknown in Sweden. And yet, this injection moulding technique can offer significant advantages and provides a lot of design freedom! full story

11 Nov 2024 TFC (thermo foam casting) or SFM (structural foam moulding) is still relatively unknown in Sweden. And yet, this injection moulding technique can offer significant advantages and provides a lot of design freedom! full storyPieter said goodbye

16 Sep 2024 Since 2015, we have been able to rely on Pieter Verbeek for all kinds of tasks in and around our factory. Now, this great man has turned 81, and it was a fitting moment to say farewell.

16 Sep 2024 Since 2015, we have been able to rely on Pieter Verbeek for all kinds of tasks in and around our factory. Now, this great man has turned 81, and it was a fitting moment to say farewell.Thank you so much for everything, Pieter! full story

10,000 Toilet bowls!

29 Jul 2024 One of the larger products Pekago manufactures is the toilet bowl cover, which we injection mould and paint for one of the aircraft interior builders among our clients. We produce these products in more than 50 colors.

29 Jul 2024 One of the larger products Pekago manufactures is the toilet bowl cover, which we injection mould and paint for one of the aircraft interior builders among our clients. We produce these products in more than 50 colors.In the spring of 2024, we delivered our 10,000th toilet bowl!

And our colleague Johnny Maelissa has inspected almost all of them for quality before delivery! full story

Large machines. Large moulds. Large products.

08 Jul 2024 Injection molding of large products naturally requires the use of large molds and large machines. Injection molding remains the same process, but very large molds require some adjustments in the processes. The heaviest mold we work with weighs around 20,000 kg. You can't just set that aside or place it into a machine without preparations.

08 Jul 2024 Injection molding of large products naturally requires the use of large molds and large machines. Injection molding remains the same process, but very large molds require some adjustments in the processes. The heaviest mold we work with weighs around 20,000 kg. You can't just set that aside or place it into a machine without preparations.But then you get something impressive: we produce with molds up to 2.10 x 1.30 m, creating products weighing around 20 kg of plastic (*). And that's a nice challenge for José Coelho, our production manager. In this blog, he enjoyes talking about his work. full story

Surveillance visit confirms continuation of AS 9100

31 Oct 2023 Lloyd's Register Quality Assurance (LRQA) has informed us, that we can continue our AS 9100 certification. We have reached this milestone and have also been able to further optimise our processes. We are very proud to announce that no nonconformaties were found during the audit!

31 Oct 2023 Lloyd's Register Quality Assurance (LRQA) has informed us, that we can continue our AS 9100 certification. We have reached this milestone and have also been able to further optimise our processes. We are very proud to announce that no nonconformaties were found during the audit!As an injection moulder for the aerospace industry, we face enormous challenges, but we are able to meet the high expectations in this industry. full story

Yet another addition to our factory: a new materials warehouse

15 May 2023 After completing an new warehouse in 2020, early 2023 the construction of an additional warehouse, dedicated to materials and semi-finished products, was started. You can see it grow in only half a minute!

15 May 2023 After completing an new warehouse in 2020, early 2023 the construction of an additional warehouse, dedicated to materials and semi-finished products, was started. You can see it grow in only half a minute!Pekago's rapid growth in recent years made external storage necessary. This caused a lot of unwanted, daily relocating. As from May 2023 however, all materials, like f.i. granulate and masterbatches, are now centrally situated directly next to our production facility. This warehouse can accomodate an extra 1.250 palles. full story

Moulds from China: not just cheaper

06 Apr 2023 "Of course moulds from China are cheaper, but that's not the main reason why we buy them there. It may sound strange, but I can get things done faster on the other side of the world than in Europe."

06 Apr 2023 "Of course moulds from China are cheaper, but that's not the main reason why we buy them there. It may sound strange, but I can get things done faster on the other side of the world than in Europe." Wil Mathijssen is jointly responsible for purchasing and technical evaluation of moulds at Pekago, and he deliberately does this in China. full story

Mould maintenance: Let every mould work like a charm

17 Jan 2023 Proper maintenance of injection moulds is essential to ensure the consistent quality of the plastic components. Moulds are exposed to acute forces and high temperatures during production. Our mould makers will pamper them to prevent damage.

17 Jan 2023 Proper maintenance of injection moulds is essential to ensure the consistent quality of the plastic components. Moulds are exposed to acute forces and high temperatures during production. Our mould makers will pamper them to prevent damage.Maykel Geerts and Pieter-Jan Luttikhuis are happy to talk about what this pampering involves in their blog on our website. full story

Design Guide: painting of injection moulded parts

01 Oct 2022 "Perfect injection moulding is not necessary, as the paint will hide any errors."

01 Oct 2022 "Perfect injection moulding is not necessary, as the paint will hide any errors."This is partly true. But accounting for post-processing work during the design and production of the plastic part can usually avoid high costs later. full story

Flexibel monitor arm for ergonomic mobile workstation

29 Jun 2020 For Alphatron Medical Innovations, Pekago has built so-called medication boxes (boxes with drawers) for AMiS for many years. We manufacture the injection-moulded parts, which we then finish, paint, process and assemble, and we install the electronics.

29 Jun 2020 For Alphatron Medical Innovations, Pekago has built so-called medication boxes (boxes with drawers) for AMiS for many years. We manufacture the injection-moulded parts, which we then finish, paint, process and assemble, and we install the electronics.We now also make the housing components of the monitor arm for the AMiS workstation. This monitor arm increases the ergonomicity of the workstation and consequently the working comfort. full story

Impact-resistant housing for parking ticket machines

20 Jun 2020 The German company Designa Verkehrsleittechnik GmbH supplies fully automated parking management systems to cities, hospitals and (international) airports. Pekago made the (impact-resistant) housing for their latest modular car park entry and exit terminal “PM Abacus” using thermoplastic foam casting. full story

20 Jun 2020 The German company Designa Verkehrsleittechnik GmbH supplies fully automated parking management systems to cities, hospitals and (international) airports. Pekago made the (impact-resistant) housing for their latest modular car park entry and exit terminal “PM Abacus” using thermoplastic foam casting. full storyAlso true for the healthcare sector: 3D-printed products are there sooner, but injection moulding is quicker

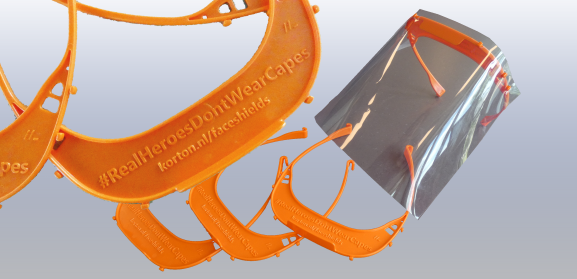

30 May 2020 In recent months, face masks have allowed healthcare staff to work in close proximity to patients and inpatients in order to administer proper care and minimise the risk of infection. However, high demand has resulted in a shortage of face masks and many healthcare institutions were unable to get hold of them!

30 May 2020 In recent months, face masks have allowed healthcare staff to work in close proximity to patients and inpatients in order to administer proper care and minimise the risk of infection. However, high demand has resulted in a shortage of face masks and many healthcare institutions were unable to get hold of them!Until recently, Korton Group just supplied IT solutions to healthcare institutions. But because of the shortage of face masks, they decided, together with some partners, to expand and print masks with a 3D printer. Though they were quickly able to scale up production to 600 masks a week, which alleviated the initial need, the need turned out to be much greater than expected. full story

"Plastics are essential for achieving the CO2 targets for the aerospace industry"

05 Mar 2020 “I dare to say that plastics will be increasingly used in the aerospace industry in the future. Plastics have important properties that traditional aircraft materials, such as aluminium, cannot compete with”. Speaking was Hermann Thorsen, our key account manager for Aircraft Interiors. In this blog, he speaks about the applications of plastics in the aircraft industry. full story

05 Mar 2020 “I dare to say that plastics will be increasingly used in the aerospace industry in the future. Plastics have important properties that traditional aircraft materials, such as aluminium, cannot compete with”. Speaking was Hermann Thorsen, our key account manager for Aircraft Interiors. In this blog, he speaks about the applications of plastics in the aircraft industry. full storyInserts in plastic: "more than a hole for a screw"

05 Mar 2020 “Inserts can literally make or break a plastic product”, laughed Jan Rijpert, our expert in the assembly of plastic components at Pekago for 28 years now. "Depending on the function and the requirements for the future use of the product, the type of insert to be used in assembly is considered as early as the design phase". full story

05 Mar 2020 “Inserts can literally make or break a plastic product”, laughed Jan Rijpert, our expert in the assembly of plastic components at Pekago for 28 years now. "Depending on the function and the requirements for the future use of the product, the type of insert to be used in assembly is considered as early as the design phase". full storyPekago expands – our new warehouse is ready!

05 Feb 2020 Pekago is growing strongly and so there was an urgent need for more space. In recent months, a new warehouse had been built next to our factory with enough space to store 2,500 pallets.

05 Feb 2020 Pekago is growing strongly and so there was an urgent need for more space. In recent months, a new warehouse had been built next to our factory with enough space to store 2,500 pallets.Watch in only 30 seconds how the warehouse was built! full story

Mould flow analysis predicts a lot about the process of injection moulding plastic products

25 Jun 2019 During a mould flow analysis, it is digitally simulated how a mould will function and how this can be optimized by adjusting the various variables. And that even before the mould has actually been made! In this way, the injection moulding process can be accurately adjusted before it has even started. full story

25 Jun 2019 During a mould flow analysis, it is digitally simulated how a mould will function and how this can be optimized by adjusting the various variables. And that even before the mould has actually been made! In this way, the injection moulding process can be accurately adjusted before it has even started. full story